MECHANICAL WORKSHOP

MECHANICAL WORKSHOP TURNING AND MILLING

- Introduction to the Mechanical Workshop and Its Functions

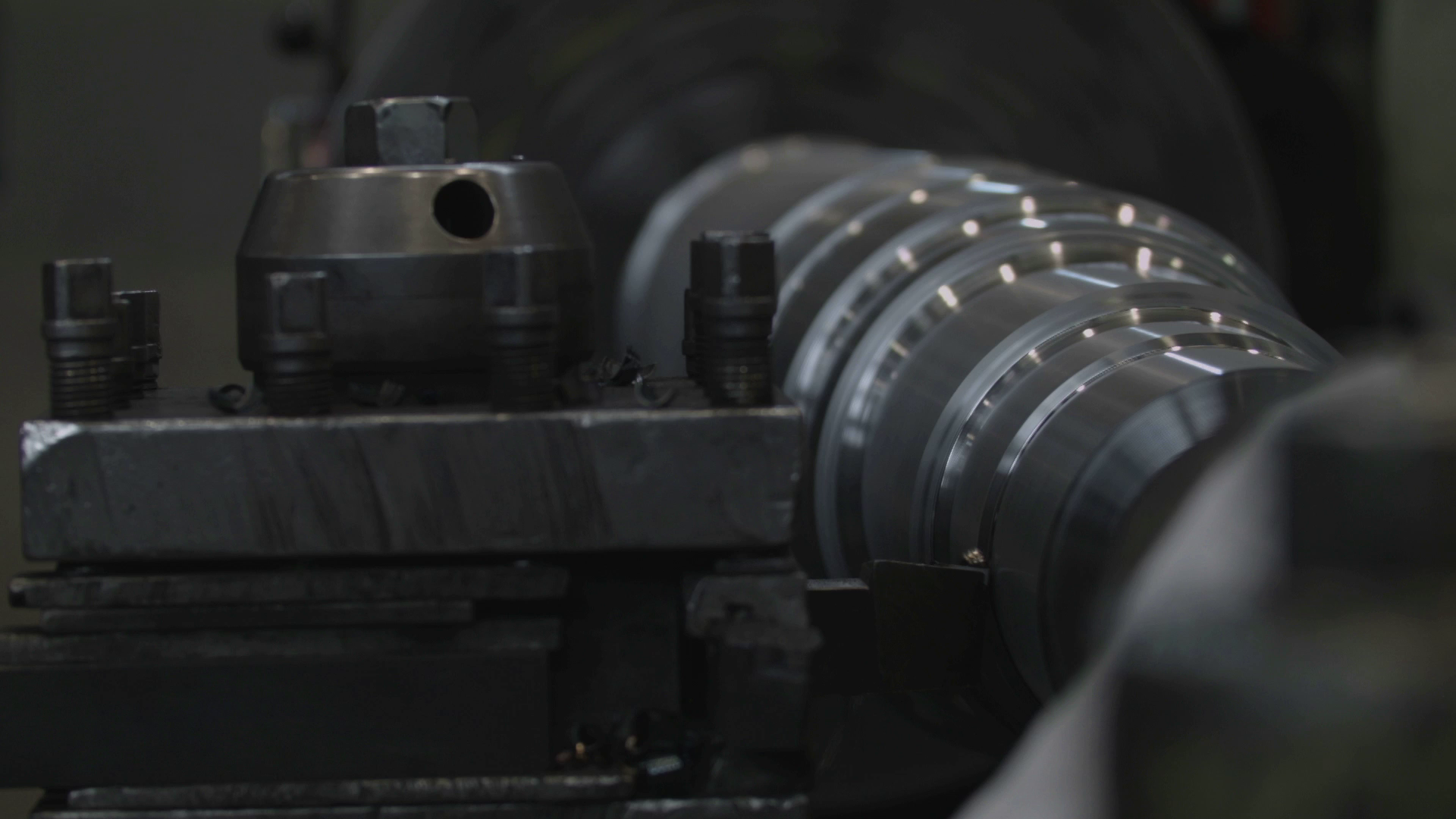

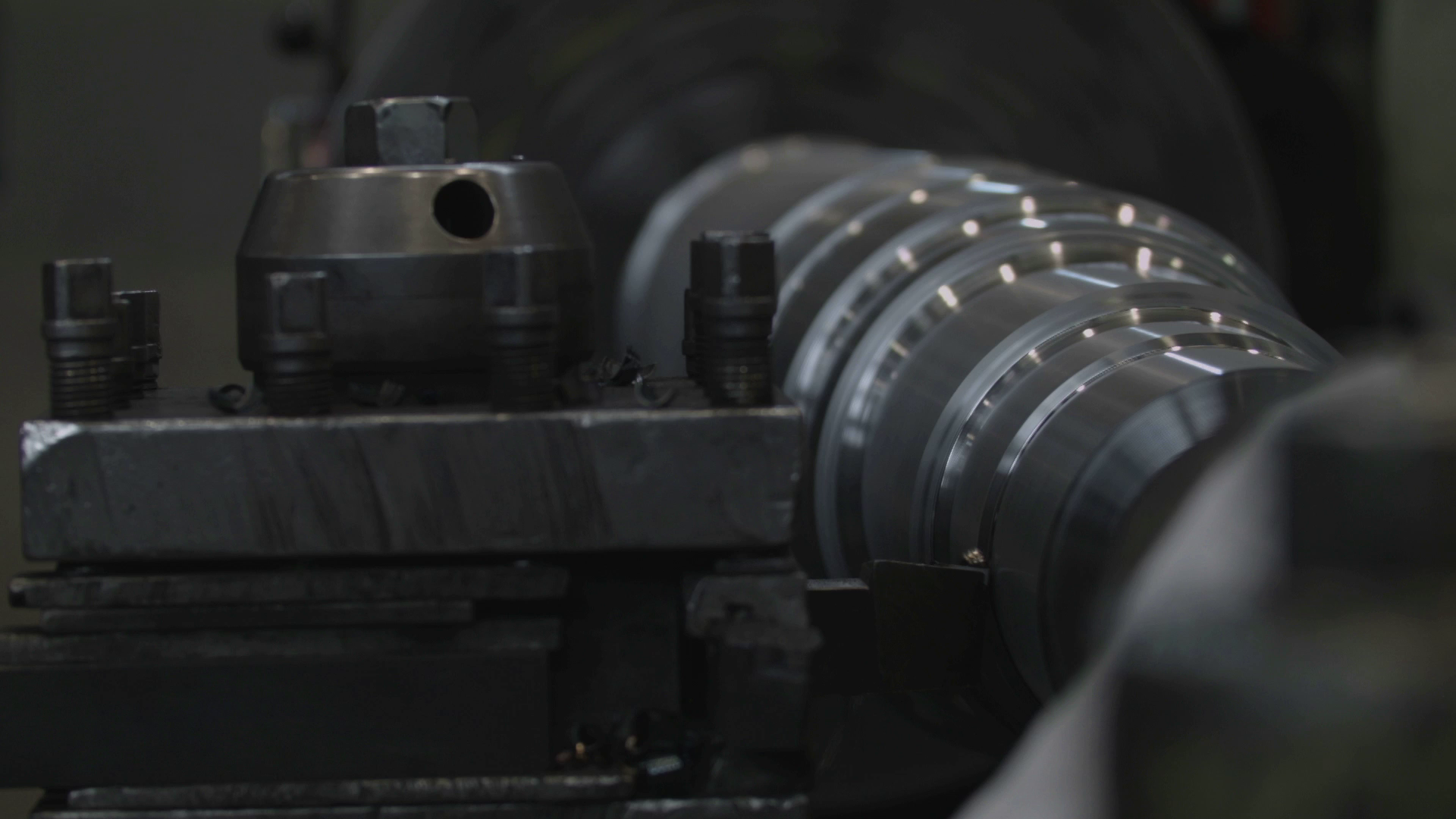

A mechanical workshop plays a pivotal role in our production, where, through the use of specialized tools such as milling machines, parallel lathes, and vertical lathes, the crucial process of excess metal removal takes place, also known as roughing, essential as a preliminary operation and foundation for the subsequent finishing and quality control phases.

- Roughing: Precise Removal of Excess Metal

Roughing is a critical phase, during which the crust created during the forging process and the excess material are meticulously removed, strictly adhering to the designs and specifications provided by our customers. This step not only ensures the accurate shaping of the piece but also facilitates the subsequent processing stages, guaranteeing high-quality results.

- Finishing Stages and Rigorous Testing

Once the removal of excess metal per design is completed, the piece enters the final phase of quality control, during which every detail is thoroughly and rigorously analyzed, ensuring that each component meets the high standards required. Furthermore, following the certification of our product through a detailed final testing procedure, the specifics can undergo the finishing phase and processes.

Discover the Incredible Capabilities of Our Facilities

Perfectly calibrated to meet all your needs in terms of custom parts processing:

Parallel lathes

N. 5 Parallel Lathes

Maximum Size

Diam. 1800 (mm) Length 16000 (mm)

Vertical lathes

N. 2 Vertical lathes

Maximum Size Diam. 3200 (mm)

Height 1600 (mm)

Gantry milling machine

Width 3000 (mm) Length 18000 (mm)

Mobile milling machine

Height 4000 (mm) Length 10000 (mm)